DIY tips: how to make a dowel joint

The dowel joint is a relatively simple joint where dowels (pins) are placed in opposite holes. It is important to work accurately, because it is very important that the holes of the various components are in exactly the same place and are drilled straight, otherwise the joint will be crooked. Read here how best to proceed!

Choose the right dowels

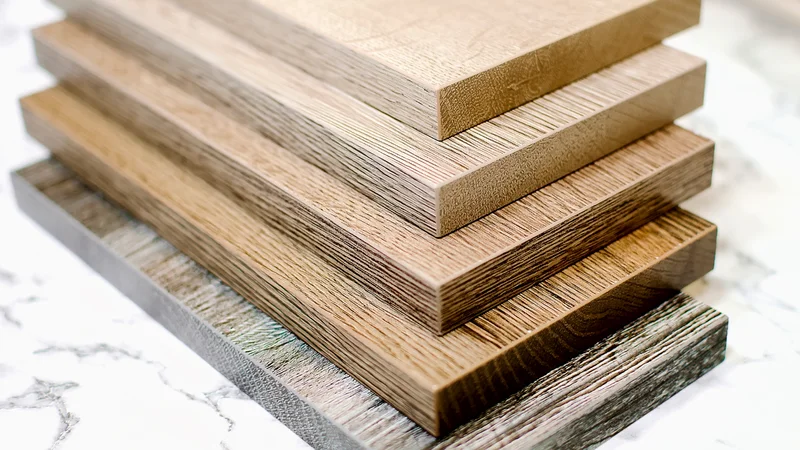

Before you start, it is good to choose the right size of dowels. A handy yardstick is: if the wood is up to 18 mm thick, 6 mm diameter dowels are sufficient. Do you want to make the connection extra strong? Then choose a thicker size of dowel. The standard length of the dowels is 30 or 40 mm. Is the wood thicker? Then also choose a dowel with a larger diameter.

Open or blind dowel joint

It is possible to make an open dowel joint. To do this, drill the holes through both parts and sand down the protruding part of the dowels later. With a blind dowel joint, the dowels are completely invisible in the material. It is very important for a dowel joint that the holes are in the same place in both parts and that they are drilled perpendicularly. For the blind dowel joint, dowel attachments are required. First drill the holes in one part of the material. Then you place the dowel attachments in these holes. These attachments have a sharp point, so that you can mark the position of the dowels with the second part when you push the part onto the attachment. An open dowel joint is somewhat easier to make because you do not need any attachments. You can choose an open or blind dowel joint based on what you like.

It is possible to make an open dowel joint. To do this, drill the holes through both parts and sand down the protruding part of the dowels later. With a blind dowel joint, the dowels are completely invisible in the material. It is very important for a dowel joint that the holes are in the same place in both parts and that they are drilled perpendicularly. For the blind dowel joint, dowel attachments are required. First drill the holes in one part of the material. Then you place the dowel attachments in these holes. These attachments have a sharp point, so that you can mark the position of the dowels with the second part when you push the part onto the attachment. An open dowel joint is somewhat easier to make because you do not need any attachments. You can choose an open or blind dowel joint based on what you like.

Drilling holes

Next, it is important to drill the holes perpendicularly into the material, just a little deeper than half the length of the dowel. This extra space is to give the glue room. A column drill or drill stand will help here, but if you do not have one, it is important that you take extra care to drill perpendicularly into the material. This is essential for a perfect result. To mark how deep you want to drill, you can put a piece of tape around the drill. This will ensure that you do not drill too deep!

Next, it is important to drill the holes perpendicularly into the material, just a little deeper than half the length of the dowel. This extra space is to give the glue room. A column drill or drill stand will help here, but if you do not have one, it is important that you take extra care to drill perpendicularly into the material. This is essential for a perfect result. To mark how deep you want to drill, you can put a piece of tape around the drill. This will ensure that you do not drill too deep!

Gluing dowels

When the holes have been drilled, the dowels can be pushed into the holes with a little wood glue. The wood glue will make the dowels slightly moist, so that they will expand and have an extra firm and filling effect. Therefore, wood glue is sufficient to use and no glue with filling power is needed. Put the glue in the hole, and possibly also a little on the dowel. Excess glue can be removed immediately with a damp cloth.

When the holes have been drilled, the dowels can be pushed into the holes with a little wood glue. The wood glue will make the dowels slightly moist, so that they will expand and have an extra firm and filling effect. Therefore, wood glue is sufficient to use and no glue with filling power is needed. Put the glue in the hole, and possibly also a little on the dowel. Excess glue can be removed immediately with a damp cloth.