Klustips: perfect frezen in plaatmateriaal

Besides routing a recess in a panel, there is much more you can do with a milling machine. Among other things, you can rout special wood joints, decorative routing, routing round edges or routing grooves. These DIY tips cover the most common types of routing. For routing, you usually need a milling machine that can accommodate different types of routers. Each cutter has its own shape and application.

Finishing edges

An edge router is used for rounding sharp edges. This cutter has a so-called run-on bearing, which allows the cutter to be held against the edge of the material and no guidance from the machine is required. The radius of the rounding is adjustable.

Milling grooves

For routing grooves, you use - how appropriate - a groove cutter. These grooving cutters are available in various widths, for different widths of groove. With a guide rail, the grooves can be cut nice and tight. Place a piece of scrap wood at the beginning and end of the material and clamp it securely so that the ends do not split when routing. A good example of when you might want to rout grooves is when you want to create a look from different slats, but simply make them from one piece.

For routing grooves, you use - how appropriate - a groove cutter. These grooving cutters are available in various widths, for different widths of groove. With a guide rail, the grooves can be cut nice and tight. Place a piece of scrap wood at the beginning and end of the material and clamp it securely so that the ends do not split when routing. A good example of when you might want to rout grooves is when you want to create a look from different slats, but simply make them from one piece.

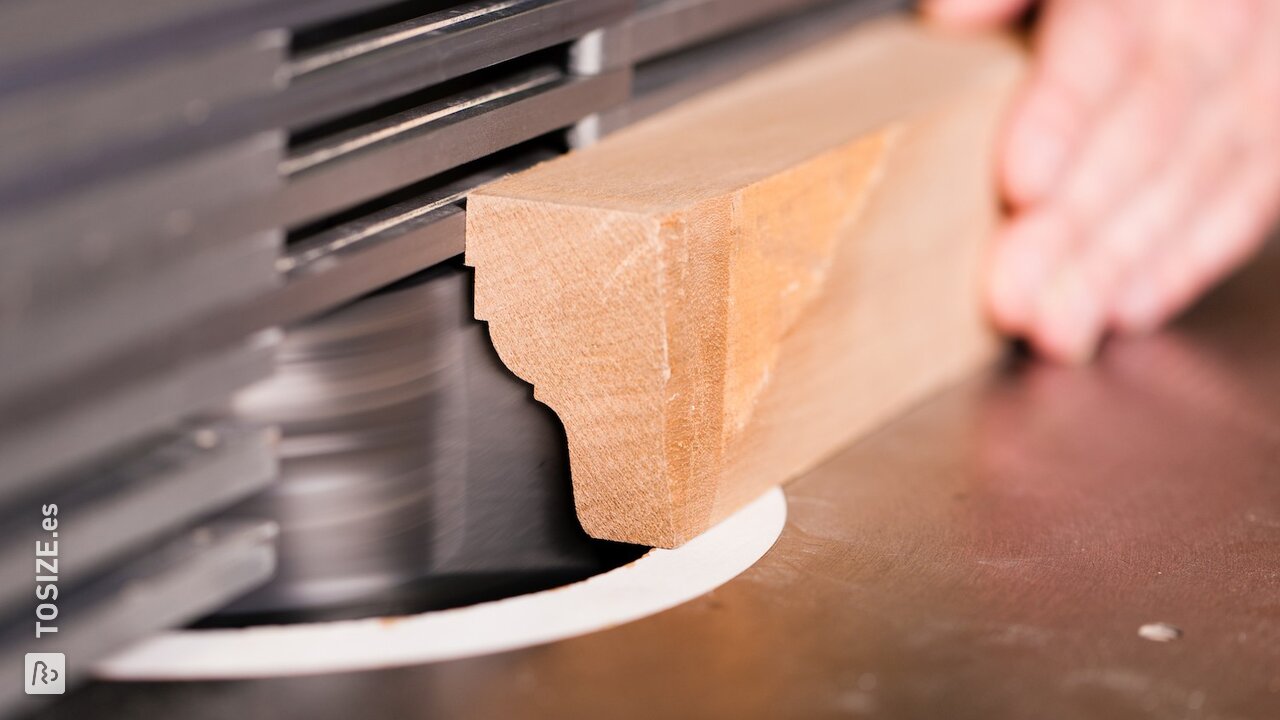

Milling a profile

There are different profile cutters that also produce different results. Many of these profile cutters have a starting bearing. Examples of profiles that can be milled are an s-profile, a bead profile, a frame profile and an ornamental profile. You should choose the right profile based on what you like, because these profiles are often for decoration. The cutters with a starting bearing can be moved along the material without a jig, so that the edge is finished off nicely and gracefully or, on the contrary, tightly.

There are different profile cutters that also produce different results. Many of these profile cutters have a starting bearing. Examples of profiles that can be milled are an s-profile, a bead profile, a frame profile and an ornamental profile. You should choose the right profile based on what you like, because these profiles are often for decoration. The cutters with a starting bearing can be moved along the material without a jig, so that the edge is finished off nicely and gracefully or, on the contrary, tightly.

Routing the handle

To make a door handle-free, for example, there is also a handle cutter. With this cutter, you make a nice notch with which you can open doors without actually fitting a handle.

To make a door handle-free, for example, there is also a handle cutter. With this cutter, you make a nice notch with which you can open doors without actually fitting a handle.

Routing the rebate

The special rebate cutter is used to cut a rebate in a frame. The glass is placed in this groove. The depth of the groove is determined by the thickness of the glass.

Milling in hinges

The easiest way to mill a hinge into a door or frame is to use a special jig. If you don't have one, you can also mark out the hinge and then hammer in the edges with a chisel. That way, you can easily see where to stop with the router. To do this, use a router that you set to the correct distance. Note: This method is only suitable for flat hinges that are usually used for external or internal doors. The most commonly used hinge for this is the ball bearing hinge. If you are going to use furniture hinges (pot hinges), then use a potentiometer.

Also check out these similar DIY tips